RA110 Spreader Beam

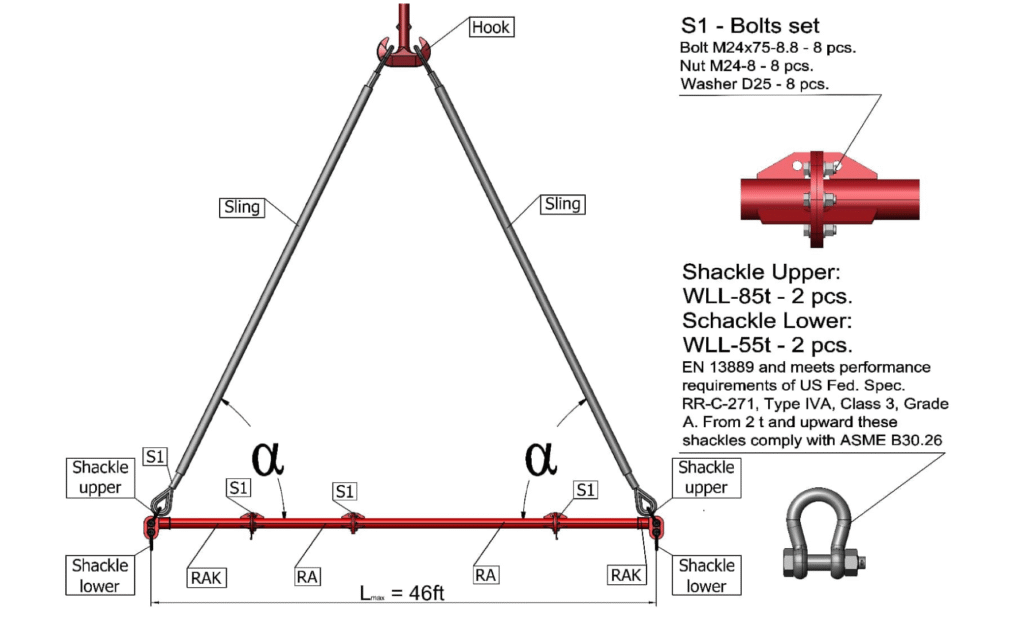

The spreader beam is designed for lifting and transporting equipment and cargo weighing up to 110t. It is adjustable every 1ft within the range of L=6ft to L=46ft, as specified in the manual. The spreader beam is intended to work solely in conjunction with lifting units equipped with appropriate chain or line slings.

Specification

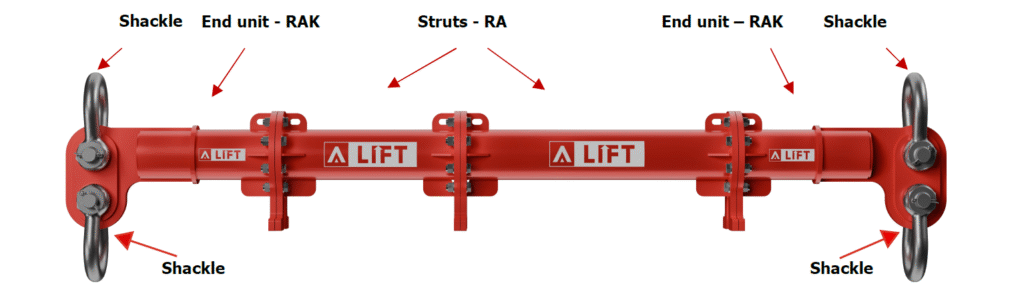

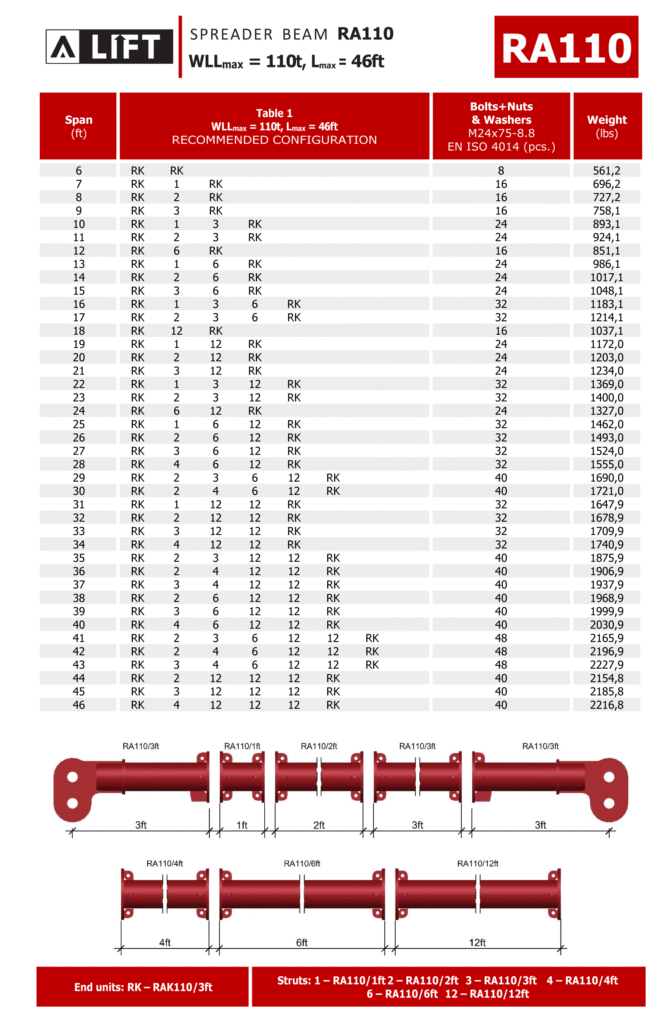

Spreader Beam RA110 WLLmax=110t, Lmax=46ft consists of:

- 2 end units RAK: 3ft

- Struts RA used to adjust the span: 1ft, 2ft, 3ft, 4ft, 6ft, 12ft

- 2 shackles WLL=55t and 2 shackles WLL=85t

- Maximum weight of the spreader beam, according to the recommended configuration, is 2216,8 lbs

- Carrying capacity from 15t to 110t

- The α angle between the beam and sling is 45° or more

- Use a bolt set to tighten (bolt+washer+nut) class 8.8. as per EN ISO 4014

- Bolt tightening torque 260 Pound-Foot. Spanner size required 36mm

- Torque wrench and ring spanner are recommended as additional equipment

Notice

- The guidelines outlined in ASME B30.20 – 2021 must be followed when using the A-LIFT equipment.

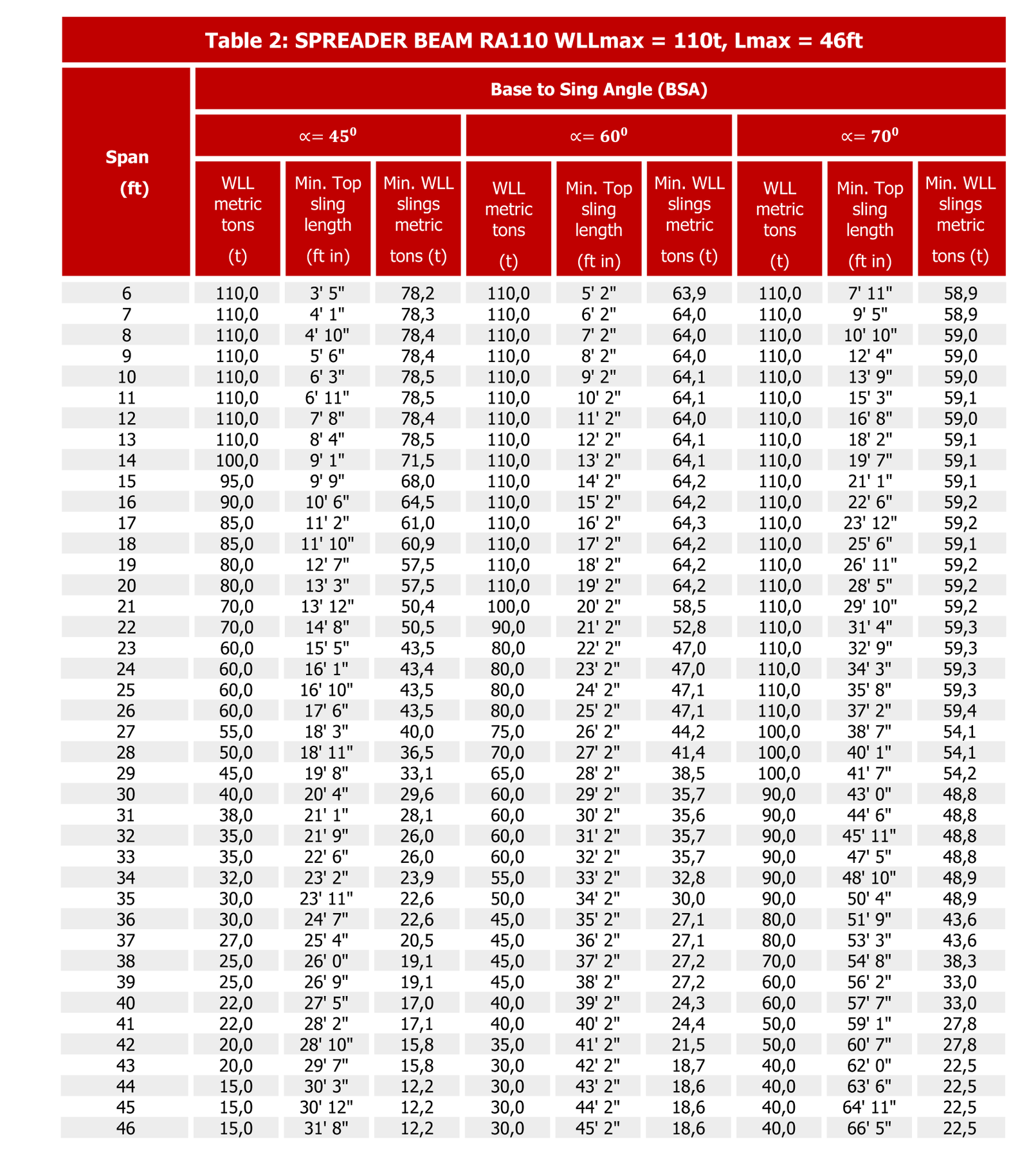

- Never exceed the indicated WLL; adhere to the WLL values listed in Table 2 for the specific sling angle used.

- To ensure the safe use of the spreader beam, the top sling length is essential – refer to Table 2.

- Under no circumstances should a load be suspended from the tube or flanges, as the spreader is designed for axial

compression and not intended for bending. - Shackles are not a part of the spreader beam. They are an additional option selected as per customer’s needs.

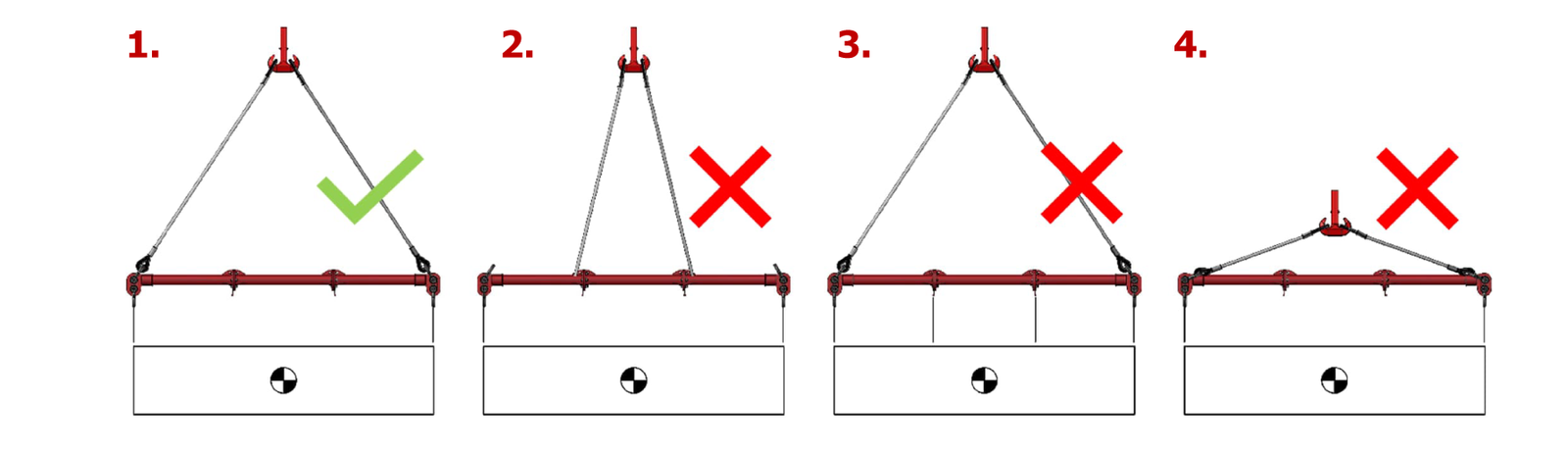

COMMON RIGGING MISTAKES

- Correct sling set up example.

- Incorrect. Upper slings are not attached to the end units.

- Incorrect. The second pair of slings below cannot be attached to the spreader beams.

- Incorrect. Sling angle α cannot be less than 45°

Assembly Method

- Verify the size of each A-LIFT component by checking its tag ID to ensure the correct size is being used.

- Arrange the beam elements on a flat surface according to Table 1 to prevent rolling.

- Before connecting, make sure that all elements and fasteners are free of any debris.

- Assemble the components using the provided bolts, nuts, and washers. Tighten bolts to the torque values specified.

- To ensure the safe use of the spreader, especially for longer spans, the quantity and quality of bolts are crucial.

- Put the jaw of the top shackle over the jaw of the end unit and attach a top sling to the top shackle’s body.

- Repeat the process for the other end of the spreader beam after inserting the top shackle pin through the shackle

and the end unit jaw. - Attach the crane hook to the free ends of the top slings.

- Attach lower slings and shackles to the lower holes of the end caps, and then connect them to the load to be lifted.

- Prior to lifting, a competent person must conduct a comprehensive inspection of the assembled spreader beam and lifting rig.

Attention!

- Ensure that the beam is loaded exclusively through the RAK end units only.

- Ensure the use of the correct top slings and avoid needless twisting of any slings.

- Keep obstacles away from the loaded spreader, as any contact could result in beam failure.

- Do not exceed the specified WLL for a particular span. Refer to Table 2.

- Avoid hanging any loads from the spreader tube, flanges, or support stands.

- Use tag lines to control movement when moving or positioning long elements or assemblies.

- Individual components might be heavy; therefore, exercise utmost caution when manual handling is necessary.